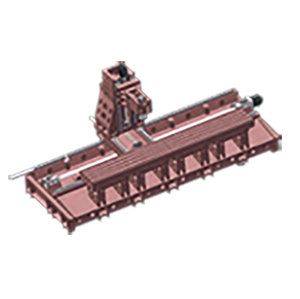

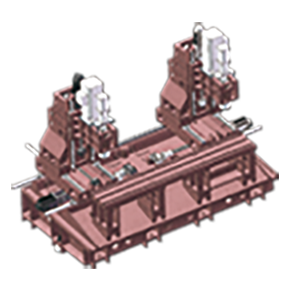

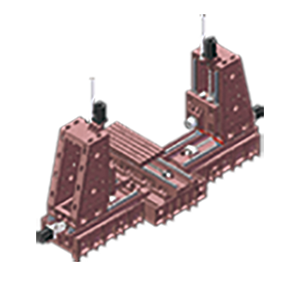

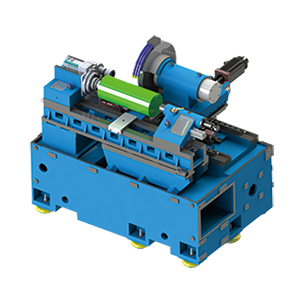

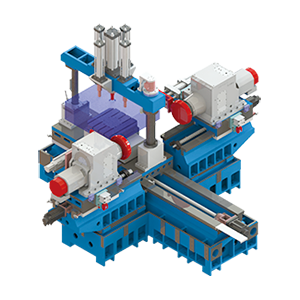

VMC650

The VMC650 is an advanced vertical milling machine, meticulously engineered to meet the diverse and demanding needs of modern manufacturing. Its robust construction and state – of – the – art features make it a reliable choice for a wide range of machining applications, from precision parts production in the aerospace industry to custom – made components in the mold and die sector.

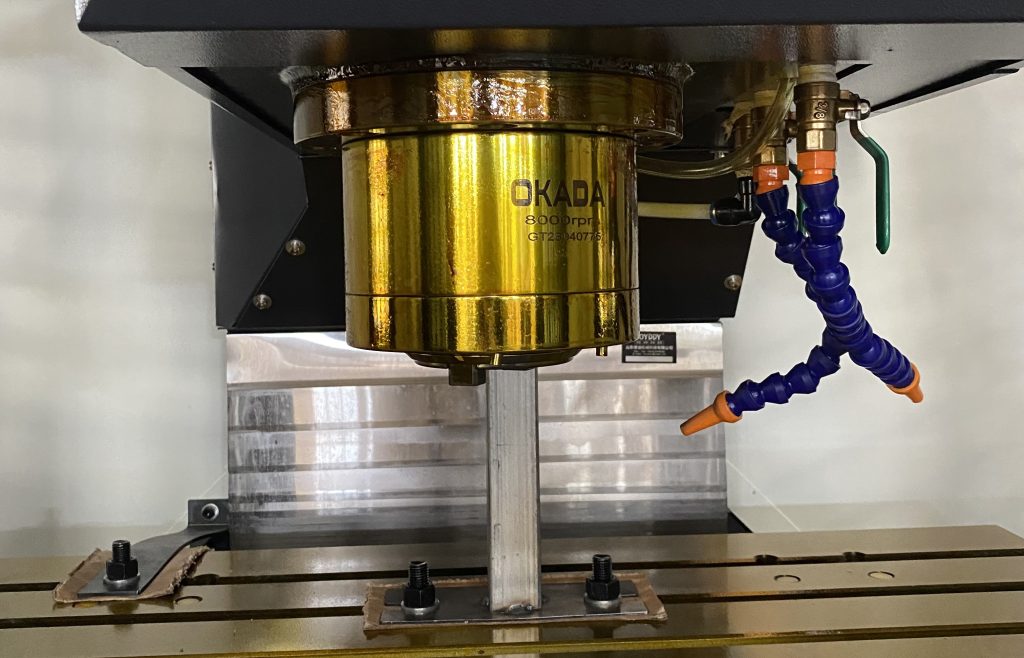

- Precise Motion Control System

- Spacious Worktable for Versatile Machining

- User – Friendly Operation Interface

Reviews

There are no reviews yet.