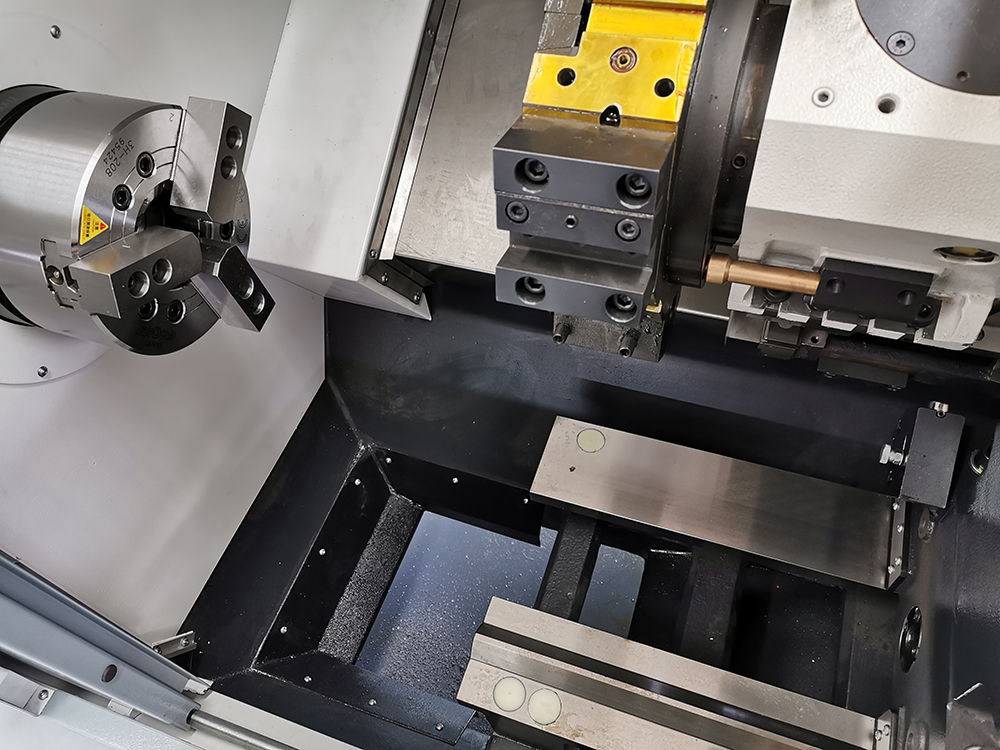

TCK63Y-1500

The TCK63Y – 1500 is a state – of – the – art CNC mill – turn machine, meticulously engineered to meet the diverse and exacting demands of modern manufacturing. By seamlessly integrating milling and turning operations into a single, high – performance platform, it offers a comprehensive and efficient machining solution.

- Empower Your Production with Unmatched Performance

- Integrated Milling and Turning for Unrivaled Productivity

- High – Torque, Ultra – Precise Spindle for Superior Machining Quality

Reviews

There are no reviews yet.