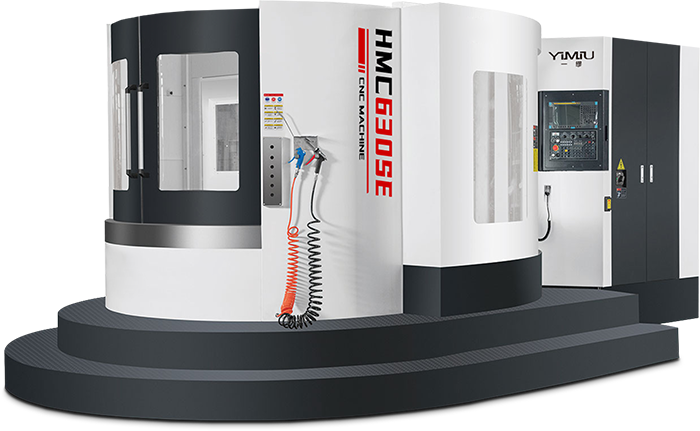

double exchange horizontal machining center

The Double Exchange Horizontal Machining Center is an advanced CNC machining solution designed for high-volume, high-precision manufacturing. Featuring a dual-pallet exchange system, this machine maximizes productivity by allowing uninterrupted machining while one workpiece is being set up. Its horizontal spindle orientation ensures superior chip evacuation, rigidity, and stability—making it ideal for heavy-duty cutting of complex parts.

- Extra-large base for stability: X and Z axes feature 55 heavy-duty linear guides, while the Y-axis boasts a rectangular hard rail for superior rigidity, ideal for heavy cutting.

- Hydraulic knife: High-stability hydraulic cutting cylinder ensures reliability with a low failure rate.

- Column hard rail: Enhanced strength and efficiency make it perfect for heavy cutting tasks.

| HORIZONTAL MILLING MACHINE | HMC630S | HMC1000S | HMC1400S | HMC630 (Inverted T) |

HMC800 (Inverted T) |

|---|---|---|---|---|---|

| Distance from spindle end to worktable(mm) | 630*630 | 1000*1000 | 1400*1400 | 630*630 | 800*800 |

| Spindle type | BT50-190 | BT50-45° | BT50-45° | BT50-190 | BT50-200 |

| X-axis travel(mm) | 1000 | 1800 | 1800 | 1000 | 1300 |

| Y-axis travel(mm) | 800 | 1000 | 1300 | 800 | 1150 |

| Z-axis travel(mm) | 850 | 1300 | 1500 | 850 | 1000 |

| Spindle speed (rpm/min) | 6000 | 3000 | 2000 | 6000 | 6000 |

| Spindle motor power | 15KW | 22KW | 22KW | 15KW | 22KW |

| Tool magazine capacity | 24 | 24 | 24 | 24 | 24 |

| Horizontal turntable | 630 turntable | 1000 turntable | 1400 turntable | 630 turntable | 800 turntable |

| HORIZONTAL MILLING MACHINE | HMC1000 (positive T) |

HMC1075 | HMC1395 | HMC800 |

|---|---|---|---|---|

| Distance from spindle end to worktable(mm) | 1000*1000 | 1300*600 | 1400*700 | 800*800 |

| Spindle type | BT50-190 | BT40-150 | BT50-190 | BT50-200 |

| X-axis travel(mm) | 1300 | 1000 | 1300 | 1300 |

| Y-axis travel(mm) | 1100 | 750 | 800 | 1150 |

| Z-axis travel(mm) | 1200 | 800 | 750 | 1000 |

| Spindle speed (rpm/min) | 6000 | 6000 | 6000 | 6000 |

| Spindle motor power | 22KW | 11KW | 15KW | 22KW |

| Tool magazine capacity | 24 | 24 | 24 | 24 |

| Horizontal turntable | 1000 turntable | 630 turntable | 630 turntable | 800 turntable |

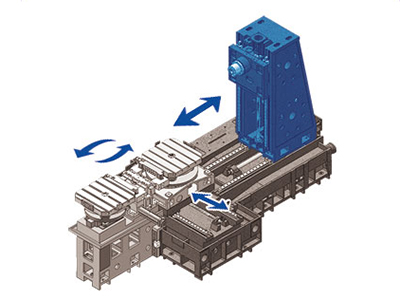

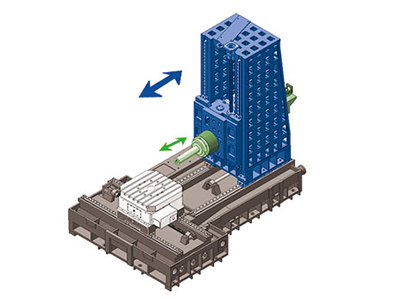

Positive T-type double exchange structure

- The worktable moves forward and backward along the Z axis, and the column moves left and right along the X axis.

- The moving parts of the structure are lighter and more suitable for precision machining.

- Suitable industry: Batch finishing of box-type workpieces.

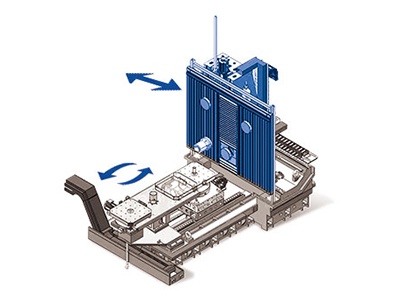

Inverted T-type double exchange structure

- The worktable moves left and right along the X-axis, and the column moves forward and backward along the Z-axis.

- Compact structure, small footprint, suitable for occasions with limited space.

- Suitable industries: Suitable for processing flat, porous or multi-faceted batch parts.

Positive T-type structure

- The worktable moves forward and backward along the Z axis, and the column moves left and right along the X axis.

- The moving part of this structure is lighter and more suitable for precision machining.

- Suitable industries: widely used in aerospace, automobile, mold, shipbuilding and general machinery industries.

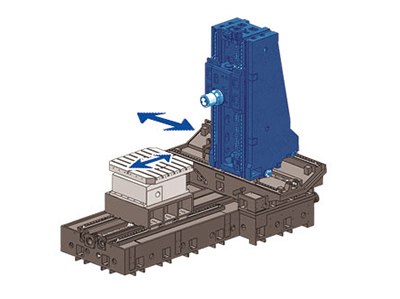

Inverted T-type telescopic spindle structure

- One-time processing of deep holes can eliminate the deviation error of long tools.

- For difficult-to-cut materials such as steel parts, stainless steel parts, forging parts, etc., the cutting performance is better and the rigidity is stronger.

- Suitable industries: The needle can be widely used in small and medium-sized boxes, engine gearboxes, new energy, wind power component processing, mold processing, and other mechanical manufacturing fields.

HANDEMO

Trusted by Industries for Precision Turning

Ready to Upgrade Your Production Line?

Buy now and enjoy free machine training!

HANDEMO

FAQ

How can I choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model. You can also send us the products drawing, we will choose the most suitable machines for you.

What's your main products of your company?

A: We specialized in all kinds of machines, such as CNC Lathe Machine, Vertical Machining Center, Lathe Machines and Customized machines.

Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City, Shandong Province, 277500 China. You are warmly welcomed to visit us.

What is your trade terms?

A : FOB, CFR and CIF all acceptable.

What's the Payment Terms ?

A : T/T, 30% initial payment when order, 70% balance payment before shipment; Irrevocable LC at sight.

What about your warranty?

A: Warranty is one year. During warranty time, if the parts are damaged because of Nonhuman factors, we will send new replaced parts for free.

How do you offer after-sale service?

A: We usually offer technical support online by wechat or whatsapp. Customer describe the problems and send videos and pictures, our technician will help to solve the problems.