Introduction

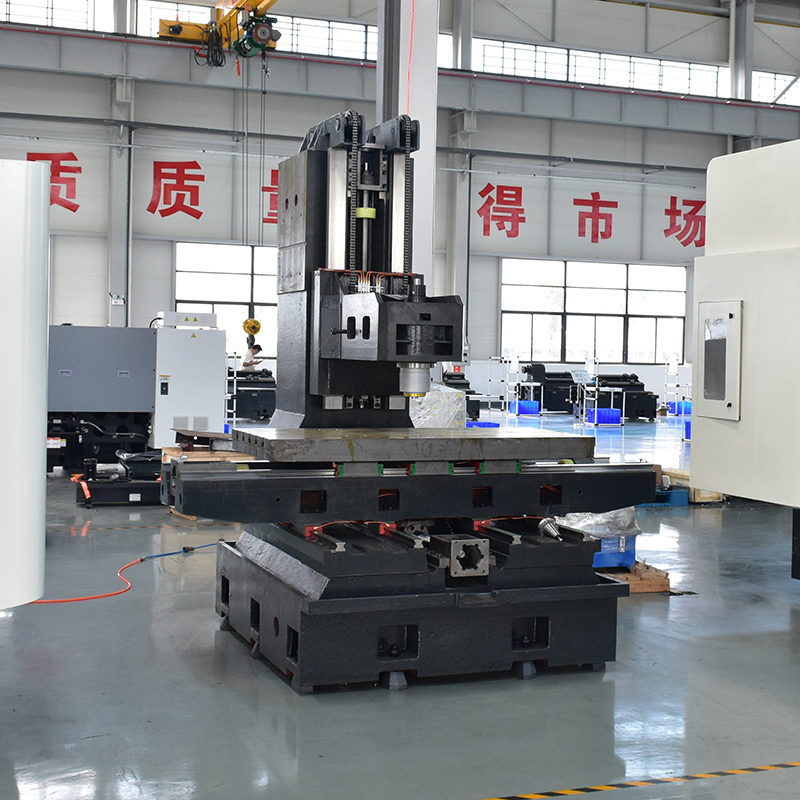

Ever looked at a complex, precisely – shaped metal part and wondered how it was made? Well, there’s a good chance a CNC milling machine was involved. In the world of manufacturing, these machines are like the Swiss Army knives, capable of a wide range of tasks. Let’s dig deeper into what makes them so special.

Defining the CNC Milling Machine

The Core Concept

A CNC milling machine is a high – tech piece of equipment. At its heart, it’s a milling machine, but with a digital twist. Traditional milling machines use manual controls to move cutting tools across a workpiece. A CNC milling machine, on the other hand, is controlled by computer – based programs. It’s like upgrading from an old – fashioned hand – operated tool to a super – smart, automated one.

The “CNC” Aspect

CNC stands for Computer Numerical Control. This means that instead of a machinist physically adjusting the tool’s position, a pre – written code guides the machine. Think of it as a set of instructions that tell the CNC milling machine exactly where to go, how fast to move, and what shape to cut. It’s like having a digital map for the cutting process.

Key Components of a CNC Milling Machine

The Machine Bed

The bed of a CNC milling machine is its sturdy foundation. It’s like the floor of a house, providing stability for all the operations. Made from heavy – duty materials, it supports the weight of the workpiece and the cutting tools. Without a solid bed, the precision of the cuts would be compromised.

Structure and Design

The bed’s structure is designed to minimize vibrations. It often has a flat surface, which allows the workpiece to be securely fastened. Different models may have variations in their bed designs, but the goal is always the same: to ensure a stable working environment for the CNC milling machine.

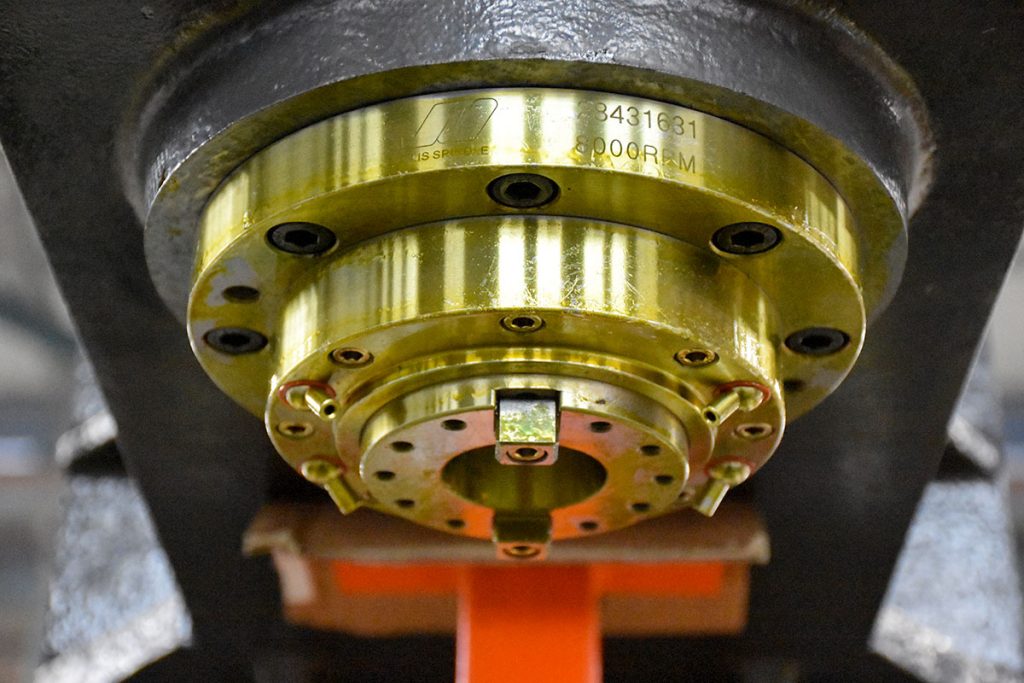

The Spindle

The spindle is where the cutting tool is attached. It’s like the hand that holds the tool and makes it spin. The speed at which the spindle rotates can be adjusted precisely. Whether it’s a slow, gentle spin for delicate cuts or a high – speed rotation for faster material removal, the spindle controls it all.

Tool Holding Mechanisms

There are various ways to hold the cutting tool in the spindle. Some use collets, which are like clamps that grip the tool tightly. Others may have more advanced tool – changing systems, allowing for quick and easy swapping of tools during the machining process.

The Table

The table is where the workpiece is placed. It can move in multiple directions, usually along the X, Y, and Z axes. This movement enables the cutting tool to reach different parts of the workpiece. It’s like a conveyor belt that can move in all directions, positioning the workpiece exactly where it needs to be for the cut.

Workpiece Mounting

Workpieces are mounted on the table using clamps, vices, or magnetic chucks. These mounting methods ensure that the workpiece stays in place during the cutting process. After all, a moving workpiece means inaccurate cuts.

How Does a CNC Milling Machine Operate?

The Programming Phase

Before the machining starts, a programmer creates a code. This code contains detailed instructions for the CNC milling machine. It’s like writing a script for a play, where every movement of the cutting tool is carefully choreographed. People can create the code using computer – aided design (CAD) and computer – aided manufacturing (CAM) software.

The Machining Process

Once the program is loaded into the machine’s control system, the magic begins. The spindle starts spinning the cutting tool, and the table moves the workpiece into position. The cutting tool then removes material from the workpiece, following the path defined in the program. It’s like a sculptor carving a masterpiece, but with incredible precision and speed.

Types of CNC Milling Machines

Vertical CNC Milling Machines

In a vertical CNC milling machine, the spindle is oriented vertically. These machines are great for machining parts with complex top surfaces. For example, they can create detailed molds or the intricate shapes on a turbine blade. It’s like having a vertical artist, painting precise designs on the workpiece.

Advantages and Applications

Vertical CNC milling machines offer good visibility of the cutting process. People commonly use them in industries like aerospace and automotive, where they need precision parts with vertical features.

Horizontal CNC Milling Machines

Horizontal CNC milling machines have a horizontally oriented spindle. They (These machines) are perfect for people to machine large workpieces and to carry out operations that require them to machine multiple sides. Think of them as the workhorses for big – scale manufacturing. They can handle jobs like machining large engine blocks or structural components.

Unique Features

These machines often have a rotary table, and you can use it to rotate the workpiece. This feature enables machining on multiple surfaces without having to re – mount the workpiece.

Advantages of Using a CNC Milling Machine

Precision at Its Best

CNC milling machines can achieve extremely high levels of precision. They can create parts with tolerances as small as a few thousandths of an inch. It’s like being able to measure and cut with the accuracy of a microscopic ruler. This precision ensures that parts fit together perfectly, reducing errors and waste.

Versatility in Machining

One of the biggest advantages of a CNC milling machine is its versatility. It can perform a wide range of operations, including cutting, drilling, boring, and threading. It’s like having a whole workshop of tools combined into one machine. Whether you need to create a simple hole or a complex 3D shape, a CNC milling machine can do it.

Increased Efficiency

These machines can work continuously without getting tired. They can run for hours, even days, producing parts at a consistent rate. It’s like having an army of tireless workers, always ready to get the job done. This increased efficiency means faster production times and lower costs.

Applications of CNC Milling Machines

In the Medical Industry

In the medical field, precision is crucial. People use CNC milling machines to create surgical instruments, implants, and prosthetics. The accuracy of these machines ensures that medical devices fit the patient’s body perfectly. It’s like creating custom – made solutions for each individual, improving patient outcomes.

In the Electronics Industry

The electronics industry relies on CNC milling machines to produce components like circuit boards and enclosures. The ability to create precise, small – scale parts is essential. It’s like building the tiny, intricate parts of a high – tech gadget, where every millimeter matters.

In the Prototyping Field

For product designers, CNC milling machines are a godsend. They can quickly turn a design concept into a physical prototype. It’s like bringing ideas to life in a tangible form. This allows designers to test and refine their products before mass production.

Customization with Shandong Handemo Technology Co., Ltd.

Tailored Solutions for Your Needs

At Shandong Handemo Technology Co., Ltd., we specialize in custom CNC milling machine services. No matter how unique your project is, we can create a solution for you. It’s like having a personal chef who can whip up a special dish just for you, but in the world of manufacturing.

Collaborative Design Process

We work closely with our clients from the initial design stage. Our team of experts uses the latest CAD/CAM software to translate your ideas into a workable program for the CNC milling machine. It’s a joint effort to ensure that the final product meets your exact specifications.

Conclusion

CNC milling machines are truly remarkable pieces of equipment. Their precision, versatility, and efficiency have transformed the manufacturing industry. Whether it’s in medical, electronics, or prototyping, they play a vital role. And with the customized services provided by Shandong Handemo Technology Co., Ltd., Shandong Handemo Technology Co., Ltd. can help customers achieve endless possibilities with these machines.

FAQs

- What is the difference between a CNC milling machine and a CNC lathe?

A CNC milling machine moves the cutting tool around the stationary or moving workpiece, while a CNC lathe rotates the workpiece against a stationary cutting tool. - Can a CNC milling machine work with soft materials like wood?

Yes, a CNC milling machine can work with soft materials like wood, as well as plastics and various metals. - How long does it take to program a CNC milling machine?

The programming time depends on the complexity of the part. Simple parts may take a few hours, while complex ones could take days or even weeks. - Do I need a large space to install a CNC milling machine?

The space required varies by machine size. Smaller models can fit in a relatively small area, but larger industrial ones need more room. - What safety precautions should I take when operating a CNC milling machine?

Wear protective gear like safety glasses, gloves, and earplugs. Keep the work area clean and ensure all guards are in place before starting the machine.