High quality

CNC Mill-Turn Machines

From Prototype to Mass Production – 40% Faster than Traditional Methods.

CNC Mill-Turn Machines

The turning-milling lathe can perform both axial and radial processing, and is a comprehensive processing method. Its processing technology includes milling, drilling, tapping, etc. The combined milling process of turning and milling is based on the workpiece as the reference point. It can perform high-speed cutting and cutting lubrication, so the processing efficiency is high. At the same time, drilling, tapping and other operations can also be performed.

- Shorten the process chain and enhance production efficiency:Combining turning and millingprocesses reduces manufacturing steps,boosting efficiency.

- CNC systems can be selected from FANUC, Siemens, etc.

- The tool setting arm can be installed for faster and more accurate tool setting, and a Renishawdetector can be installed to detect the workpiece size in real time.

| TCK56Y/600Y SERIES | TCK56Y | TCK56Y-1000 | TCK600Y | TCK600Y-1000 |

|---|---|---|---|---|

| Rotation diameter (mm) | 500 | 560 | 600 | 600 |

| Cutting diameter (mm) | 360 | 350 | 430 | 430 |

| Processing length (mm) | 500 | 1000 | 500 | 1000 |

| Main motor power | 30KW | 30KW | 30KW | 30KW |

| Chuck diameter | 8″/10″ | 6″/8″/10″ | 8″/10″ | 8″/10″ |

| Spinde hole diameter (mm) | 65 | 65 | 65 | 65 |

| Bar diameter (mm) | 50 | 50 | 50 | 50 |

| Number of tools | ’12 | 12 | ’12 | ’12 |

| Drive tool/turret power | Radial/Axial | Radial/Axial | Radial/Axial | Radial/Axial |

| Y-axis travel (mm) | ±30 | ±30 | ±50 | ±50 |

| TCK70Y/80Y SERIES | TCK70Y-1000 | TCK70Y-2000 | TCK70Y-3000 | TCK80Y-1500 | TCK80Y-3000 |

|---|---|---|---|---|---|

| Rotation diameter (mm) | 720 | 720 | 720 | 1100 | 1100 |

| Cutting diameter (mm) | 480 | 480 | 480 | 680 | 680 |

| Processing length (mm) | 1000 | 2000 | 3000 | 1400 | 2900 |

| Main motor power | 37KW | 37KW | 37KW | 43 | 43 |

| Chuck diameter | 10″/12″/15″ | 10″/12″/15″ | 10″/12″/15″ | 12″/15″ | 12″/15″ |

| Spinde hole diameter (mm) | 85 | 85 | 85 | 104 | 104 |

| Bar diameter (mm) | 75 | 75 | 75 | 90 | 90 |

| Number of tools | 12 | 12 | 12 | 12 | 12 |

| Drive tool | Radial/Axial/7.5KW | Radial/Axial/7.5KW | Radial/Axial/7.5KW | Radial/Axial/7.5KW | Radial/Axial/7.5KW |

| Y-axis travel (mm) | ±75 | ±75 | ±75 | ±75 | ±75 |

| DOUBLE SPINDLE SERIES INTERPOLATION Y-AXIS SERIES | TCK600SY | TCK3100SY | TCK2100SYY | TCK2100LY | TCK3100LY |

|---|---|---|---|---|---|

| Rotation diameter (mm) | 600 | 750 | 300 | 650 | 750 |

| Cutting diameter (mm) | 350 | 500 | 300 | 300 | 500 |

| Processing length (mm) | 500 | 1000 | 1000 | 500 | 1000 |

| Main motor power | 30KW/11KW | 37KW/30KW | / | 30KW | 37KW |

| Chuck diameter | 8″/6″ | 10’/8″ | 10’/8″ | 8’/10″ | 10’/12″ |

| Spinde hole diameter (mm) | 65 | 85 | / | 65 | 85 |

| Bar diameter (mm) | 50 | 75 | / | 50 | 75 |

| Number of tools | ’12 | 12 | 12 | 12 | 12 |

| Drive tool/turret power | Radial/Axial/5.5KW | Radial/Axial/7.5KW | / | Radial/Axial/5.5KW | Radial/Axial/7.5KW |

| Y-axis travel (mm) | ±50 | ±100 | ±100 | ±50 | ±100 |

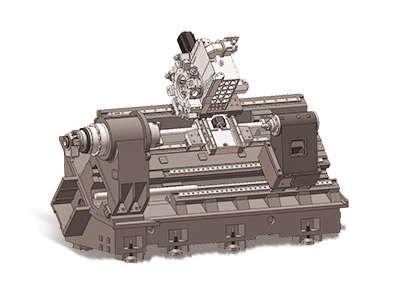

Straight Y turning and milling compound

- One clamping can realize turning, milling, drilling,tapping, boring and reaming multi-process processing.

- Save labor costs and land costs.

- Suitable industry: batch processing of high-precision and complex workpieces.

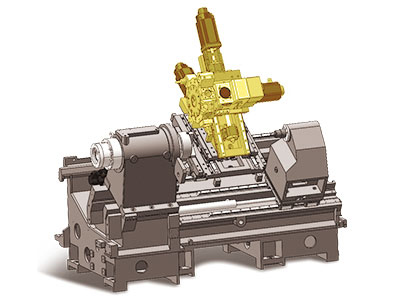

Interpolation Y-axis milling compound

- Doosan same interpolation Y structure, with oil-water separation.

- 30° beveled integral bed with stable cutting force, programmable hydraulic tailstock.

- Suitable industries: The tailstock adopts a rotary center structure to ensure the processing accuracy and stability of slender shafts.

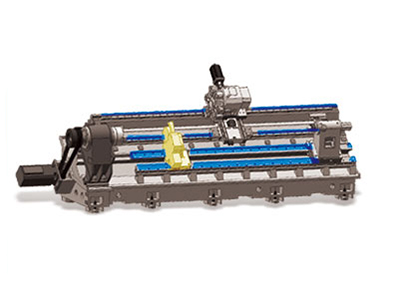

Dual spindle & interpolation Y-axis milling and turning compound

- Doosan same interpolation Y structure.

- One clamping can complete the whole sequence of turning,milling, planing, drilling, gear hobbing, etc.

- Suitable industries: aerospace, automobile manufacturing, equipment, mold manufacturing and energy equipment, etc.

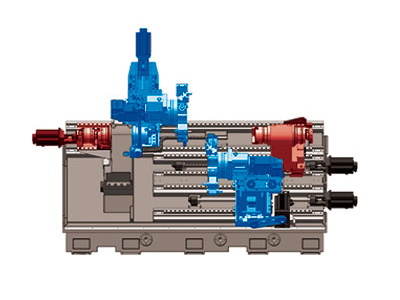

Dual spindle & dual turret milling and turning

- One machine can replace 6 machines: replacing 2 lathes, 2 milling machines, and 2 automated trusses.

- Dual spindles and dual turrets for simultaneous processing, greatly shortening processing time.

- Suitable industries: automotive parts, aerospace, mold manufacturing, medical equipment and other high-precision industries.

HANDEMO

Trusted by Industries for Precision Turning

Ready to Upgrade Your Production Line?

Buy now and enjoy free machine training!

HANDEMO

FAQ

How can I choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model. You can also send us the products drawing, we will choose the most suitable machines for you.

What's your main products of your company?

A: We specialized in all kinds of machines, such as CNC Lathe Machine, Vertical Machining Center, Lathe Machines and Customized machines.

Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City, Shandong Province, 277500 China. You are warmly welcomed to visit us.

What is your trade terms?

A : FOB, CFR and CIF all acceptable.

What's the Payment Terms ?

A : T/T, 30% initial payment when order, 70% balance payment before shipment; Irrevocable LC at sight.

What about your warranty?

A: Warranty is one year. During warranty time, if the parts are damaged because of Nonhuman factors, we will send new replaced parts for free.

How do you offer after-sale service?

A: We usually offer technical support online by wechat or whatsapp. Customer describe the problems and send videos and pictures, our technician will help to solve the problems.