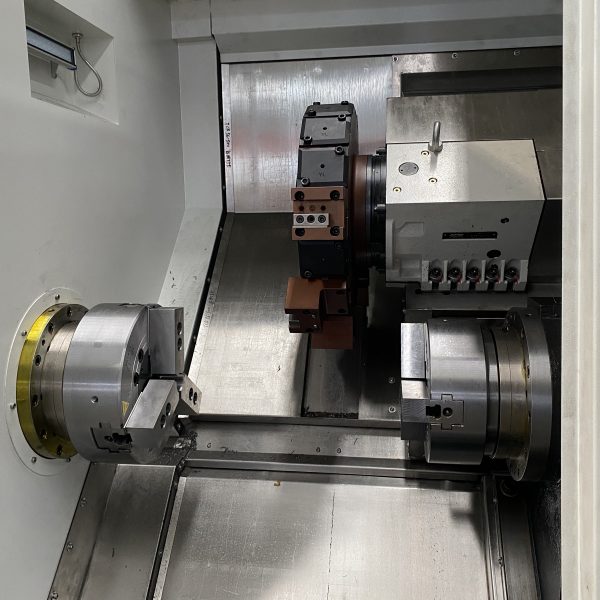

TCK2100LY

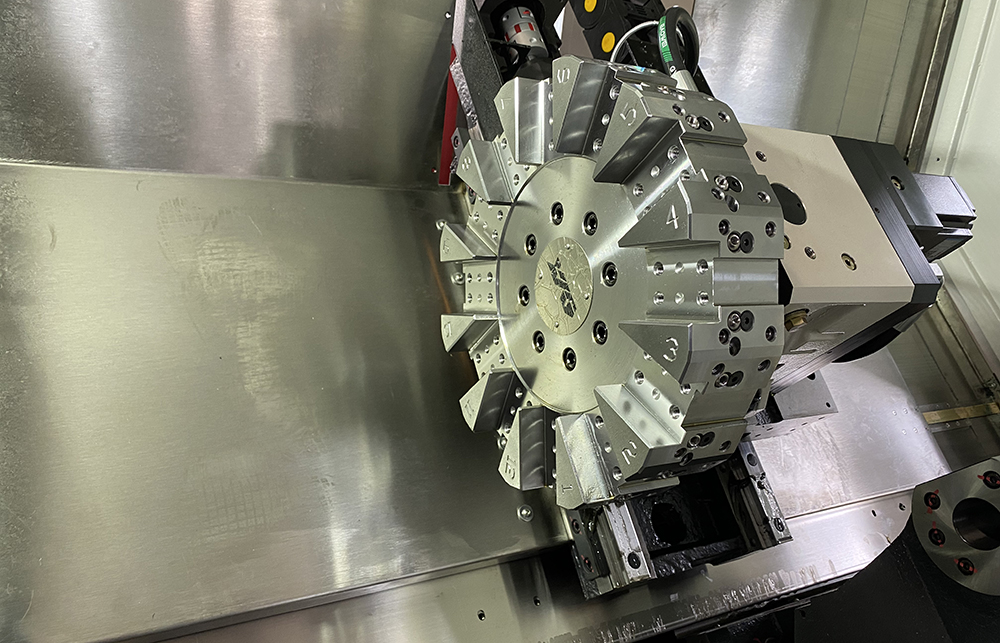

CNC Mill-Turn Machines – TCK2100LY is a high-performance milling machining center that integrates CNC turning and milling functions, suitable for machining high-precision complex parts. It adopts multi-axis linkage control, equipped with dual spindles and power turrets, supports turning, milling, drilling, tapping and other composite processing, reduces repeated clamping of workpieces, and improves processing efficiency and precision.

- Features the same interpolation Y-axis structure as Doosan

- Equipped with a BMT55 powered turret and a 5.5 kW motor for enhanced cutting performance.

- The spindle is a high-torque 30 kW electric spindle, offering high precision and constant torque at low speeds.

Reviews

There are no reviews yet.