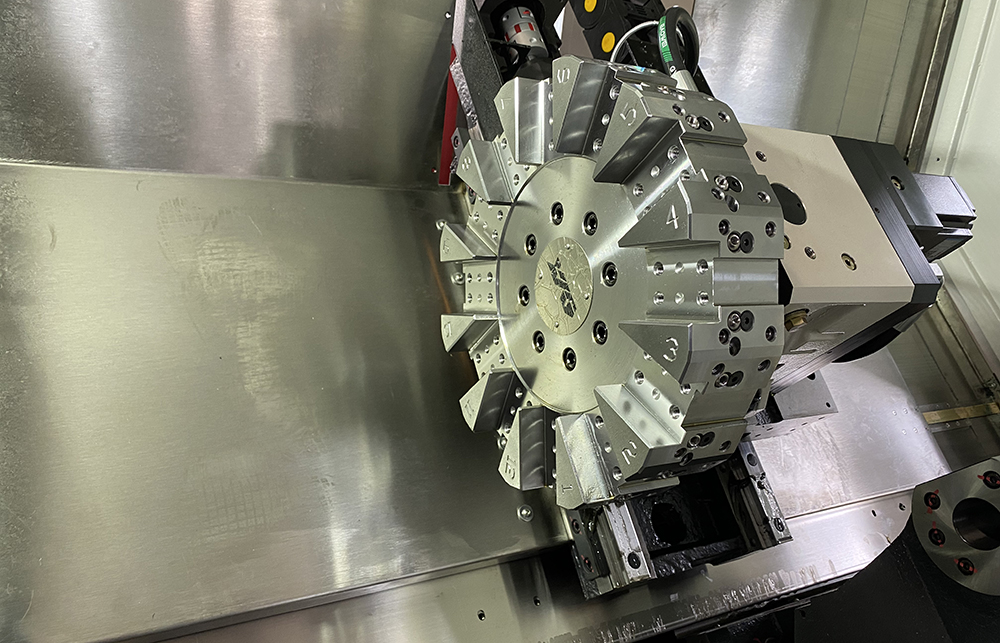

TCK63Y-1000

CNC Mill-Turn Machines-TCK63Y-1000 is a powerful CNC turning and milling machine that integrates the advantages of lathes and milling machines. Under the horizontal layout, it can flexibly realize various processing operations such as turning and milling.

- Integrated Milling and Turning for Unrivaled Efficiency

- High – Torque, Ultra – Precise Spindle for Superior Results

- Intuitive CNC Interface for Effortless Operation

Reviews

There are no reviews yet.