Hey there! Ever wondered how those super – precise parts in your gadgets or cars are made? Chances are, a CNC lathe played a big role. Let’s dive in and find out what this amazing machine is all about.

What Exactly is a CNC Lathe?

The Basics

A CNC lathe, or Computer Numerical Control lathe, is a modern machining marvel. It’s like a super – smart version of the traditional lathe. You know, those old – school machines that spin a workpiece while a cutting tool shapes it? Well, a CNC lathe takes that concept and adds a whole new level of precision and control.

The “CNC” Part

The “CNC” in CNC lathe stands for Computer Numerical Control. It’s not just a fancy name. This means the machine is controlled by a computer program. Instead of a machinist manually adjusting the tool’s position, the computer tells the lathe exactly where to move. It’s like having a super – accurate digital map for the cutting tool.

Components of a CNC Lathe

The Bed

The bed of a CNC lathe is like the sturdy foundation of a house. It’s a long, heavy – duty structure that supports all the other parts. It needs to be really stable to ensure the lathe can work with precision. After all, if the base is wobbly, the final product won’t be accurate.

The Headstock

Think of the headstock as the “engine” of the lathe. It holds the workpiece and makes it spin. The speed at which it spins can be precisely controlled, which is crucial for different cutting operations. Whether you need a slow, gentle spin or a high – speed whirl, the headstock can do it.

The Tailstock

The tailstock is like the support crew. It helps hold long workpieces in place. When you’re working on a long, thin rod, for example, the tailstock provides that extra support at the other end, preventing the workpiece from vibrating or moving around too much.

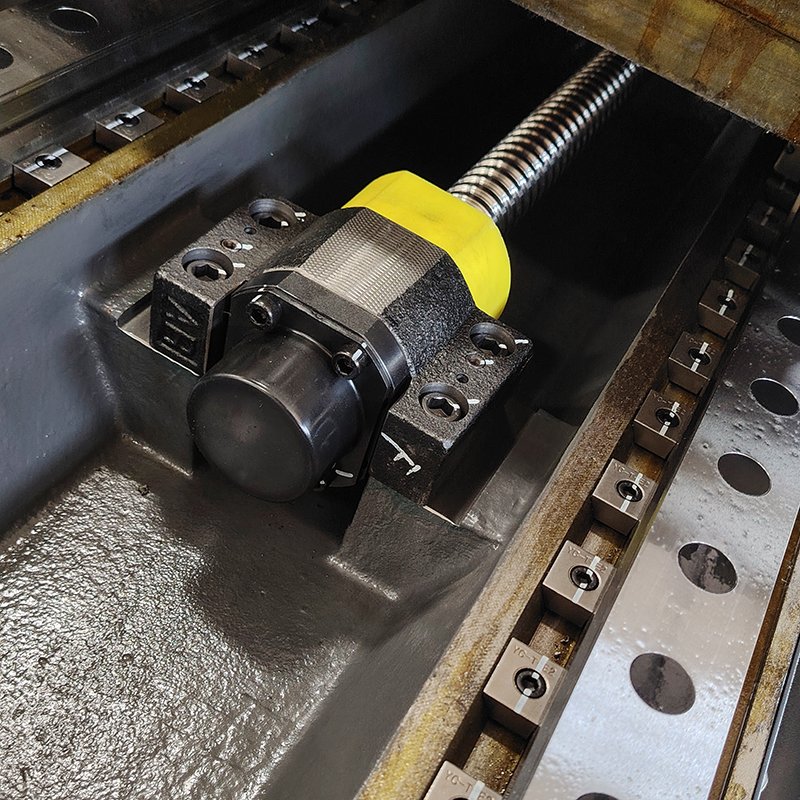

The Tool Post

This is where the cutting tools are mounted. It’s like a toolbox on the lathe. Different tools can be quickly swapped in and out of the tool post, depending on the type of cutting, drilling, or threading you need to do.

How Does a CNC Lathe Work?

Programming the Magic

First, a programmer creates a detailed code. This code tells the CNC lathe everything – from the speed of the spindle to the exact path the cutting tool should take. It’s like writing a step – by – step recipe for the lathe to follow.

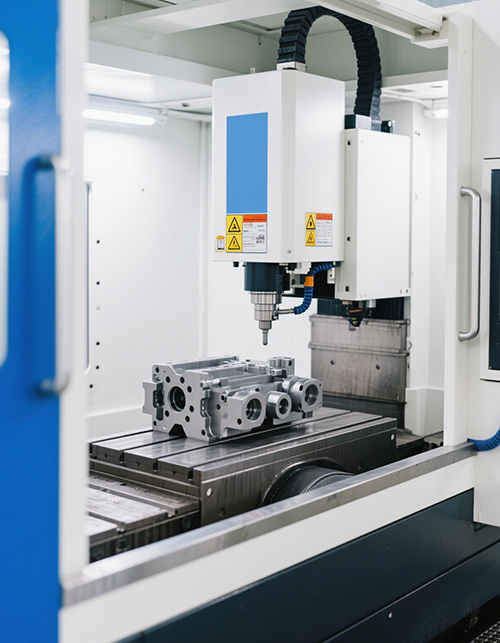

The Cutting Process

Once the program is loaded, the lathe springs into action. The workpiece starts spinning, and the cutting tool, guided by the computer, moves in to shape it. The tool can move in multiple directions – horizontally, vertically, and even diagonally – to create all sorts of shapes.

Types of CNC Lathes

Horizontal CNC Lathes

These are the most common type. The spindle in a horizontal CNC lathe lies horizontally. They’re great for working on long, cylindrical parts. Think of pipes or shafts. If you’ve ever seen the long, smooth rods in an engine, a horizontal CNC lathe might have been involved in making them.

Vertical CNC Lathes

In a vertical CNC lathe, the spindle is vertical. This type is perfect for working on large, flat – faced parts. Imagine making the large circular plates used in some industrial machinery. A vertical CNC lathe would be the go – to machine for that.

Advantages of Using a CNC Lathe

Precision Beyond Compare

CNC lathes can achieve tolerances as small as a few thousandths of an inch. That’s insanely precise! It’s like being able to draw a perfect line with a pencil that’s a million times thinner than a human hair. This precision means parts fit together perfectly, reducing waste and improving the quality of the final product.

Increased Productivity

Since the machine is controlled by a computer, it can work non – stop without getting tired. It can produce parts much faster than a human – operated lathe. It’s like having a team of tireless workers who never need a break.

Flexibility in Design

With a CNC lathe, you can create complex shapes with ease. The computer program can be adjusted to make any design you can dream up. It’s like having a 3D printer for metal parts, but with even more control.

Applications of CNC Lathes

In the Automotive Industry

CNC lathes are all over the automotive world. They make parts like engine components, axles, and gears. Without CNC lathes, cars wouldn’t be as reliable or efficient. It’s like the lathes are the secret ingredient in making a great – running car.

In the Aerospace Industry

Aerospace parts need to be extremely precise. Aerospace manufacturers use CNC lathes to make parts for airplanes and spacecraft. From turbine blades to landing gear components, the aerospace industry relies on CNC lathes to ensure safety and performance.

In the Medical Field

In the medical world, precision is life – saving. Manufacturers use CNC lathes to make surgical instruments and implants. CNC lathes create the exact shapes and smooth surfaces required for these medical devices.

Customization with CNC Lathes

Tailoring Parts to Your Needs

At Shandong Handemo Technology Co., Ltd., we offer customized CNC lathe services. Whether you need a one – of – a – kind part for a prototype or a large batch of customized components, our CNC lathes can do it. It’s like having a personal tailor for your metal parts.

Design Your Own

We work with you to turn your ideas into reality. If you have a unique design in mind, our team can help you program the CNC lathe to bring it to life. It’s a collaborative process that ensures you get exactly what you need.

Conclusion

CNC lathes are truly amazing machines. They’ve revolutionized the manufacturing world with their precision, productivity, and flexibility. Whether you’re in the automotive, aerospace, or medical industry, or you just need a customized metal part, it can handle the task. And with companies like Shandong Handemo Technology Co., Ltd. offering top – notch CNC lathe products and customized services, the possibilities are endless.

FAQs

- What materials can a CNC lathe work with?

It can work with a variety of materials, including metals like steel, aluminum, and copper, as well as plastics and some types of wood. - How much does a CNC lathe cost?

The cost of a CNC lathe can vary widely depending on its size, capabilities, and brand. Small, basic models can start at a few thousand dollars, while large, high – end ones can cost hundreds of thousands. - Do I need special training to operate a CNC lathe?

Yes, operating a CNC lathe requires training. You need to learn how to program the machine, set up the tools, and ensure safe operation. - Can a CNC lathe be used for mass production?

Absolutely! CNC lathes are great for mass production due to their high precision and ability to work continuously. - How accurate are CNC lathes?

CNC lathes can be extremely accurate, with some achieving tolerances as small as 0.0001 inches.

Tags: CNC Slant Bed Lathe , Vertical Milling Machine , Horizontal Machining Centes