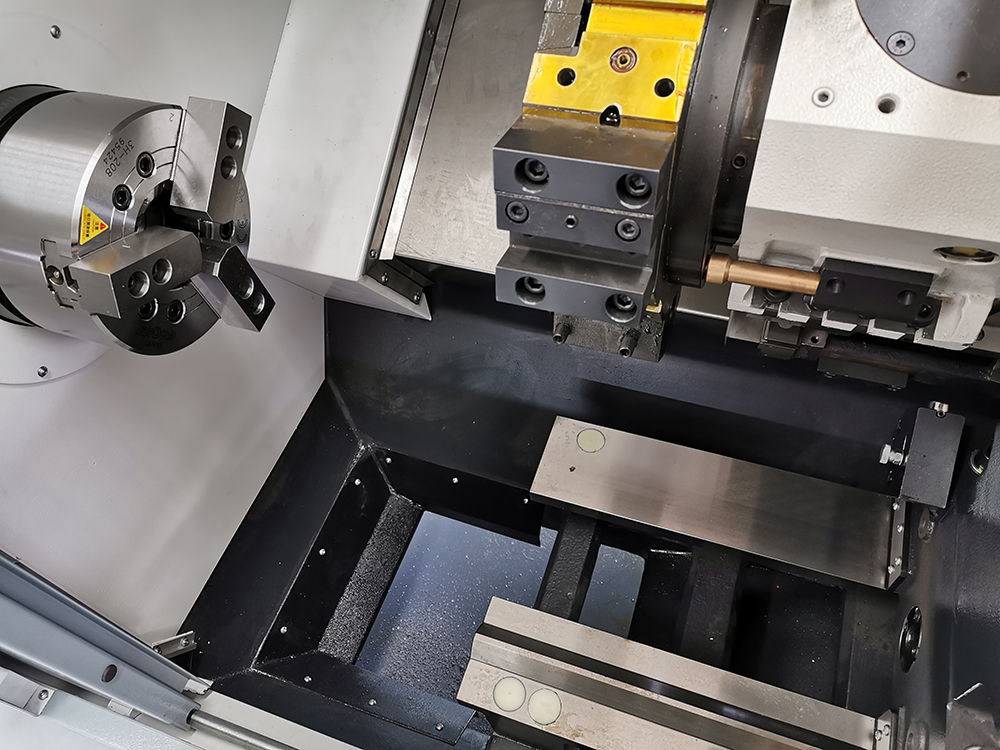

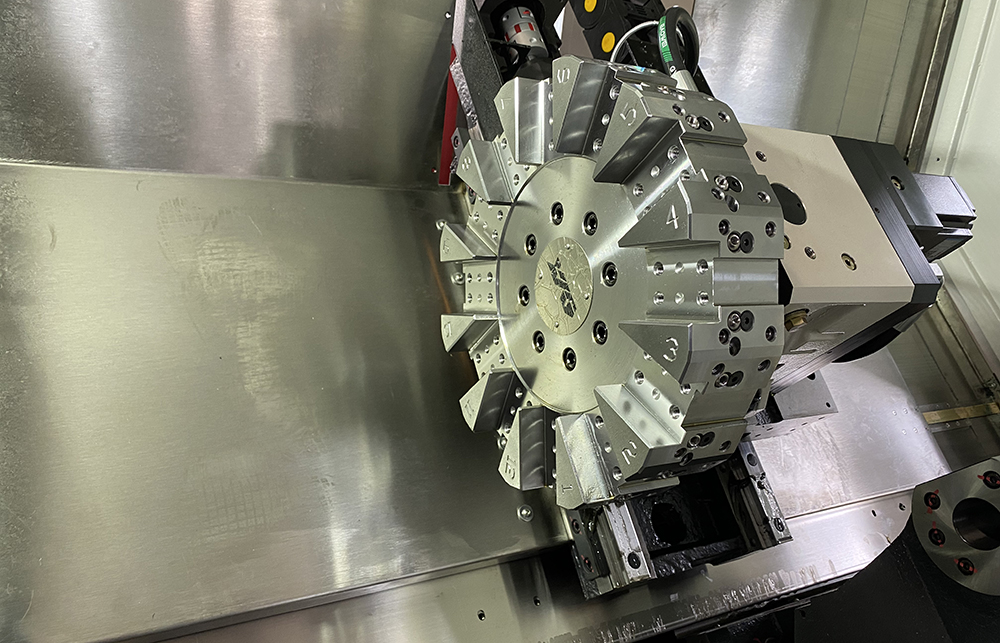

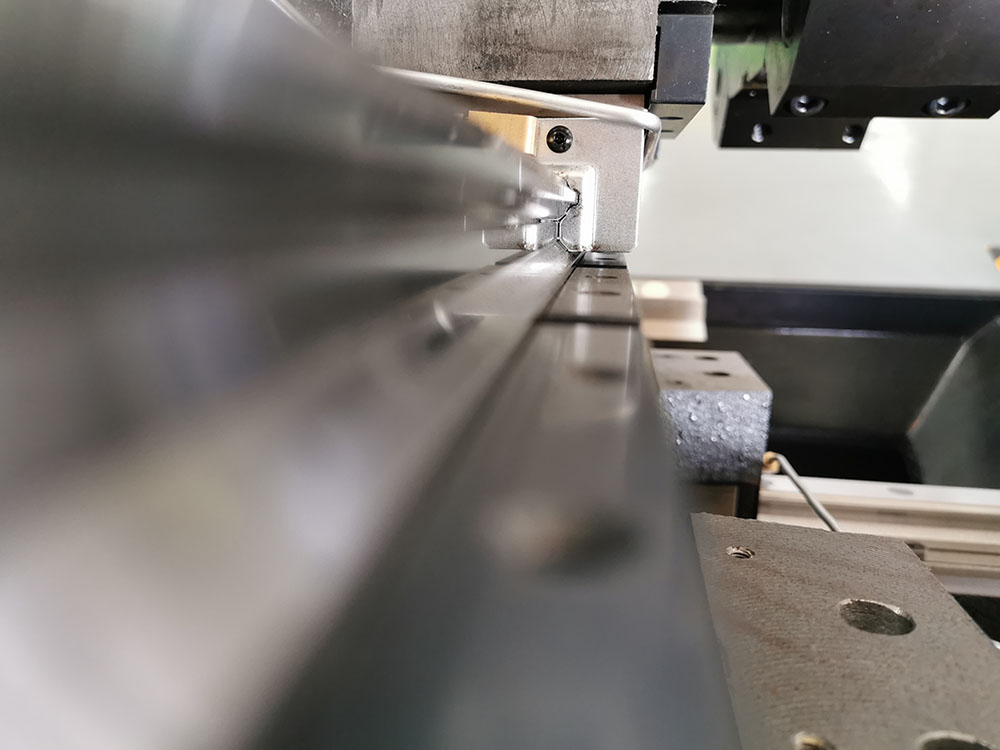

TCK600S

The TCK600S is a cutting – edge CNC slant lathe, meticulously designed to meet the evolving needs of modern manufacturing. Its slant – bed configuration offers enhanced stability during high – speed operations and seamless chip removal.

- High – Torque Spindle for Heavy – Duty Machining

- Ultra – Precise Control System Ensuring Micron – Level Accuracy

- Spacious Work Envelope for Diverse Workpiece Sizes

Reviews

There are no reviews yet.