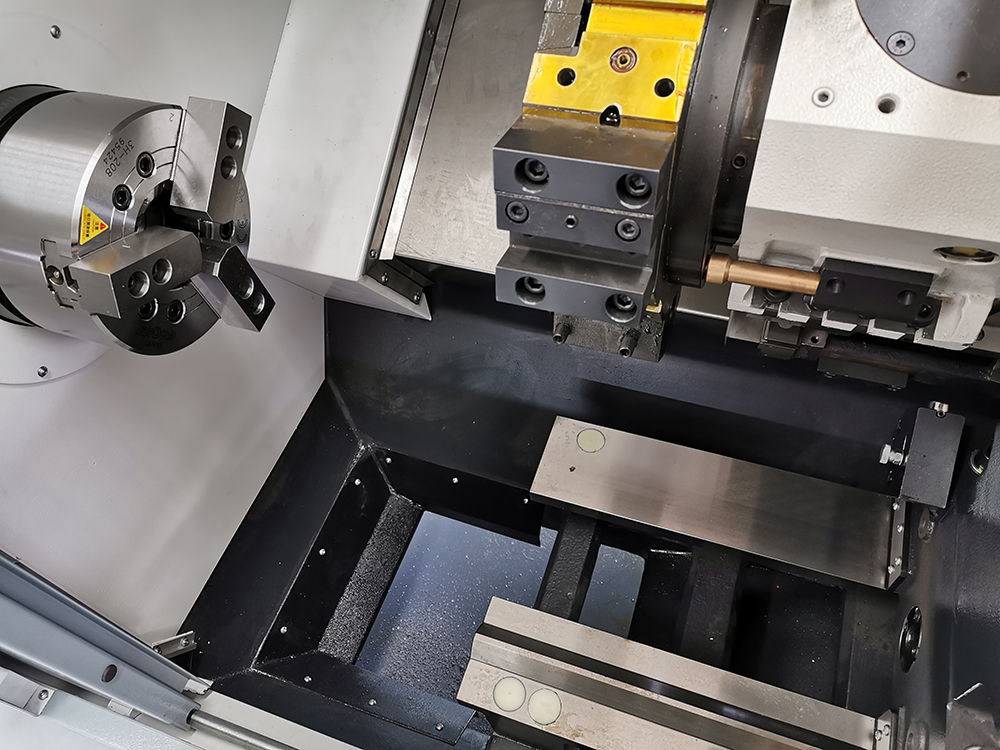

TCK56-1000

The TCK56 – 1000 is a paragon of modern machining technology. Engineered with a slant – bed structure, it offers enhanced stability during high – speed operations and efficient chip evacuation. This lathe combines a super – high – torque spindle, capable of handling the most rugged materials, with an ultra – precision control system that ensures every cut is executed with micron – level accuracy. Its extra – long bed design is tailored for machining extended workpieces, making it a versatile solution for a wide range of industries.

- Super – High – Torque Spindle for Extreme Machining

- Ultra – Precision Control for Micron – Level Accuracy

- Extra – Long Bed for Extended Workpiece Machining

Reviews

There are no reviews yet.