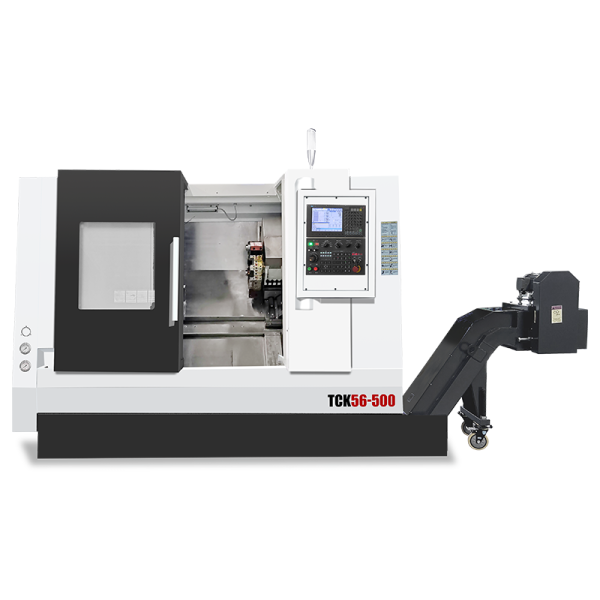

TCK56-500

The TCK56 – 500 is a state – of – the – art CNC slant lathe engineered to meet the most demanding machining requirements. Its slant – bed design offers enhanced stability and chip evacuation, while the advanced features ensure high – quality machining of a wide range of parts.

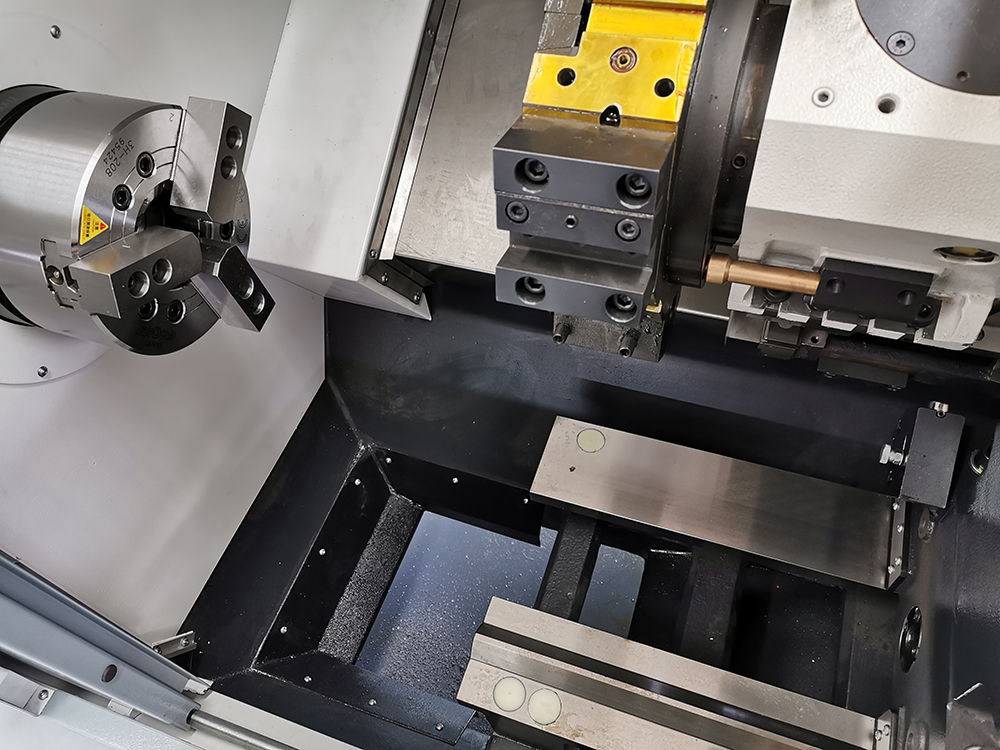

- High – Torque Spindle for Heavy – Duty Machining

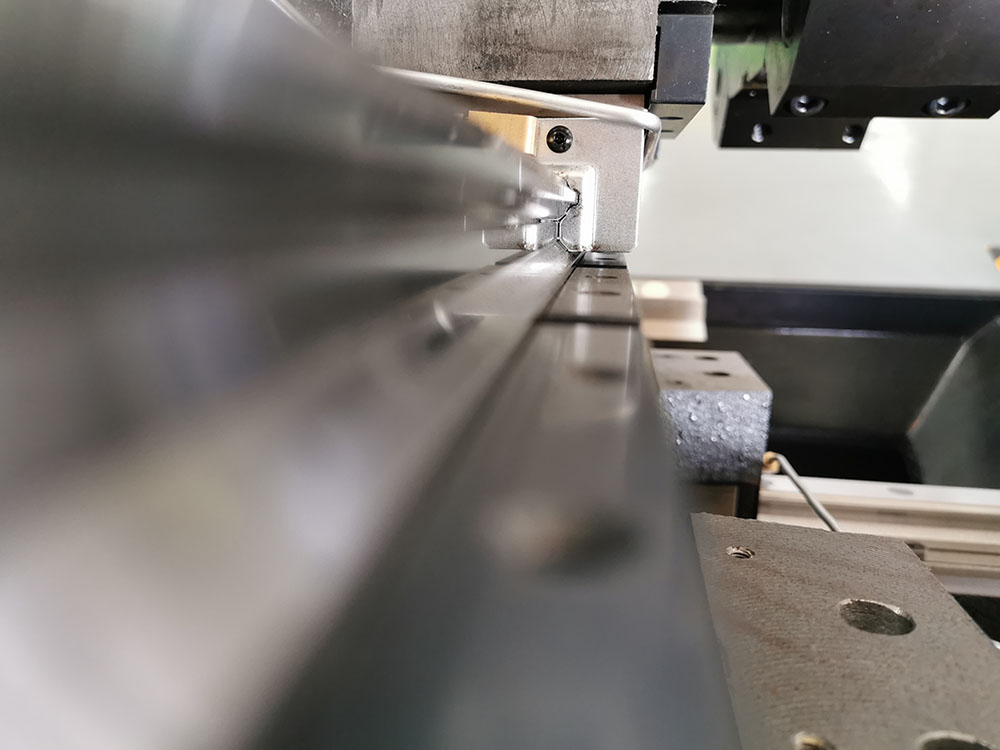

- Exceptional Precision with Advanced Control System

- Extended Bed for Long – Shaft Machining

Reviews

There are no reviews yet.