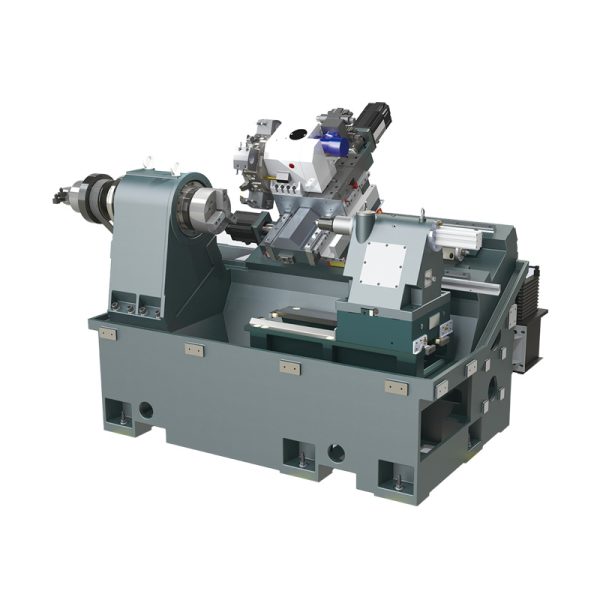

TCK50

The TCK50 CNC Slant Lathe is engineered for precision – centric manufacturing. Its slant – bed design offers enhanced stability during high – speed operations. This lathe combines cutting – edge technology with robust construction, providing manufacturers across industries with a reliable solution for complex part machining.

- The lathe body is made of HT300 integrated casting.

- Compact structural design minimizes footprint, reducing space costs.

- Hard rail tailstock reduces workpiece reactive force.