Vertical Milling Machine

The Vertical Milling Machine is a high-performance machining tool designed for precision milling, drilling, and cutting operations. With its robust construction and advanced features, this machine is ideal for workshops, manufacturing facilities, and engineering applications requiring accuracy and efficiency.

| VERTICAL MILLING MACHINE | VMC650 | VMC855 | VMC1160 | VMC1160P | VMC1370 | VMC1690 |

|---|---|---|---|---|---|---|

| Workbench size (mm) | 1000*400 | 1000*500 | 1200*600 | 1200*600 | 1400*700 | 1600*800 |

| Distance from spindle end to worktable (mm) | 650/100 | 670/120 | 720/120 | 720/120 | 870/120 | 850/150 |

| Spindle type | BT40-120 | BT40-150 | BT40-150 | BT40-150 | BT40-150 | BT50-190 |

| X-axis travel (mm) | 650 | 800 | 1100 | 1100 | 1300 | 1600 |

| Y-axis travel (mm) | 400 | 550 | 600 | 600 | 700 | 900 |

| Z-axis travel(mm) | 550 | 550 | 600 | 600 | 750 | 700 |

| Spindle speed (rpm/min) | 8000/12000 | 8000/12000 | 8000/12000 | 8000/12000 | 8000/12000 | 6000/12000 |

| Spindle motor power | 5.5KW | 7.5KW | 11KW | 11KW | 15KW | 15KW |

| Tool magazine capacity | 16 | 24 | 24 | 24 | 24 | 24 |

| Feed speed (mm/min) | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Optional fourth axis | YES | YES | YES | YES | YES | YES |

Our exclusive services

“We look forward to hearing from you and helping you find the perfect machining solution for your business.”

Warranty

We offer a comprehensive 5 - year warranty on all our CNC slant bed lathes, ensuring your peace of mind.

Spare parts network

Relying on a complete spare parts storage network, we provide original spare parts in the shortest time.

Onsite training

We provide on-site guidance and training to ensure your team can quickly master equipment operation skills.

Casting body

The casting structure is complex, with good wear resistance and shock absorption.

High speed spindle

Our vertical milling machines feature powerful spindles and fast feeds up to 15,000 rpm, significantly reducing machining time, allowing you to complete projects faster without sacrificing quality.

24-Position Tool Magazine

Featuring 24 tool positions and seamless automatic switching, it ensures uninterrupted machining for higher output.

Stable CNC system

Our vertical milling machines offer flexible CNC system options. You can choose from systems such as FANUC and Siemens, ensuring you get the control system that meets your specific machining needs and preferences.

Multiple structure display

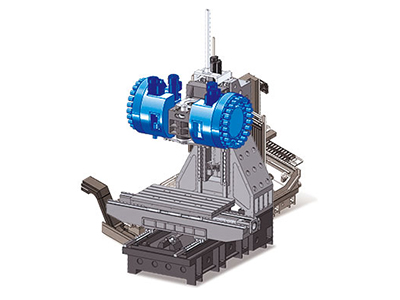

Double tool magazine structure

- Compared with traditional tools, more tools are used, and processing efficiency is improved by 56%-60%.

- High flexibility and diversified processing, reducing non-cuttingtime, and can realize complex process integration.

- Suitable industries: mold bases, mold frames, molds, and various parts processing that use many tools.

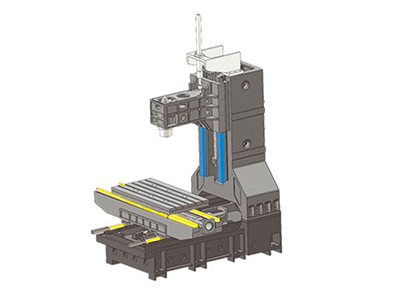

Three-hard rail

structure

- Can withstand large cutting forces and vibrations ensuring machining stability and precision.

- Can effectively resist deformation of machine tools during long-term use.

- Suitable industries: Widely used in industries with high machining precision and stability requirements.

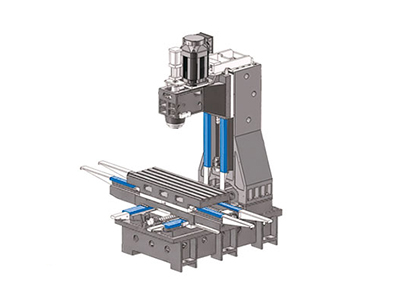

Two-wire and one-hard structure

- Combines the advantages of linear rails and hard rails, with high speed and strong load-bearing capacity.

- Convenient for rigid cutting and maintaining the accuracy of the linear rails.

- Suitable industries: Suitable for processing scenarios with high requirements for processing accuracy and need to withstand large loads.

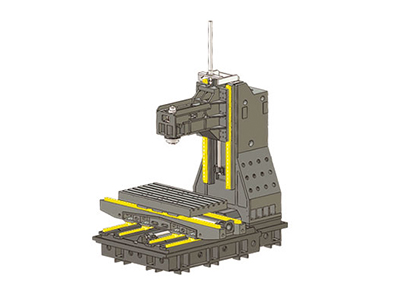

Three-line rail

structure

- Fast speed, high precision.

- Small friction coefficient, fast response.

- Suitable industry: Suitable for customers with high processing precision requirements.

Trusted by Industries for Precision Turning

Choice for all industries

Our vertical milling machines deliver top performance and reliability across a wide range of industries.

Automotive: Engine parts, transmission components

Mechanical Engineering: High-precision machine parts

Medical Technology: Surgical instruments, implants

Aerospace: Critical aircraft components